THE PROFLOW GAS BYPASS SYSTEM

Innovative Technology Built on Real Mining Experience

The ProFlow Gas Bypass System represents a breakthrough in managing gas borehole intersections in underground coal mining. Developed by mining professionals with over 20 years of experience in Australia's gassiest coal seams, our patent-pending solution addresses the critical issues of safety, efficiency, and production continuity.

Unlike traditional approaches that can be time-consuming and inconsistent, our system provides a standardised method for quickly sealing and redirecting gas flow when boreholes are intersected during mining operations. This practical innovation means less downtime, enhanced safety, and more reliable production schedules.

SYSTEM OVERVIEW

The Proflow Gas Bypass System is engineered specifically to address the challenges of underground coal mining environments. Our solution combines innovative design with practical field experience to create an effective and easy-to-implement system.

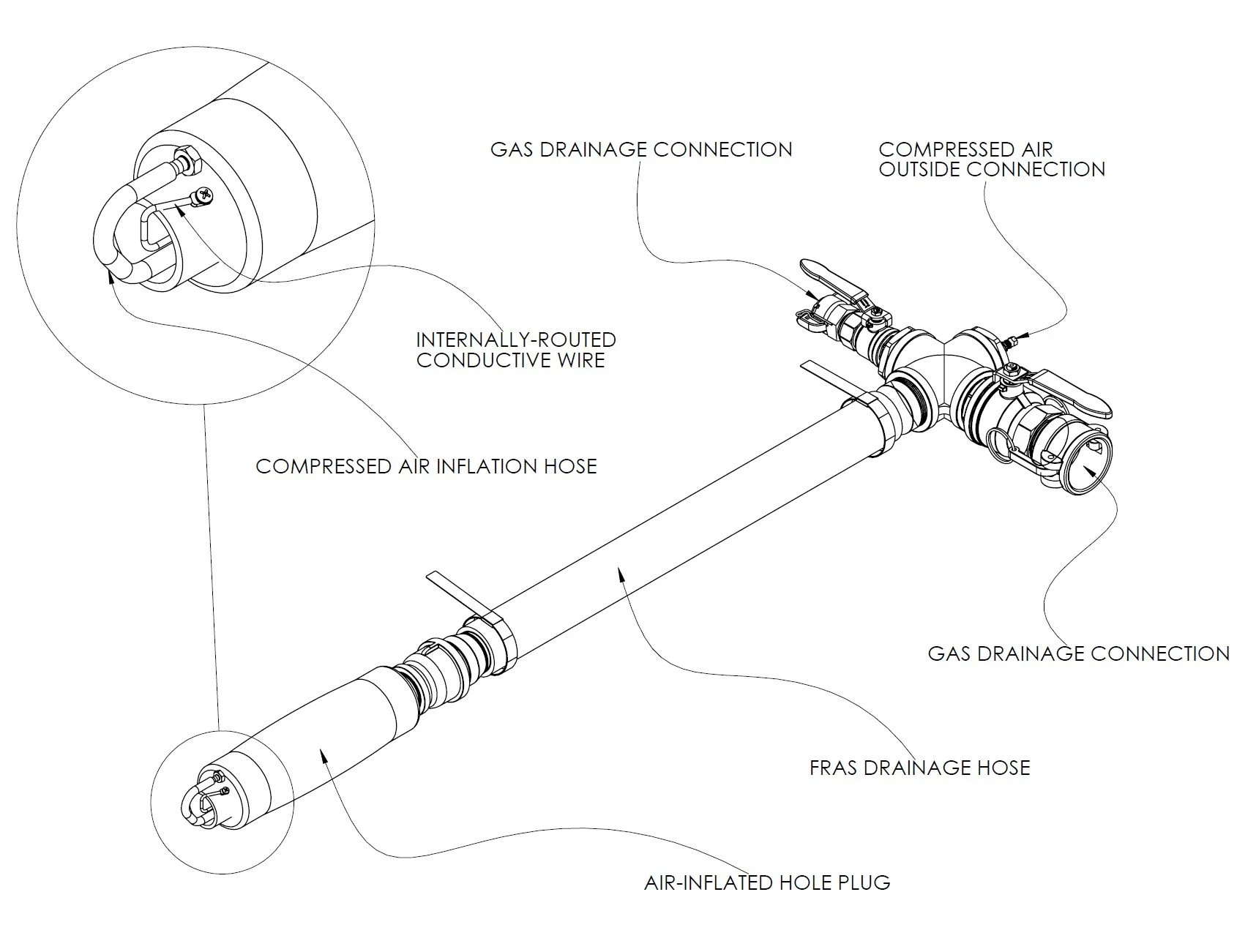

Core Components:

• Custom-designed sealing mechanism for rapid deployment

• Bypass technology that redirects gas flow to appropriate drainage systems

• FRAS-compliant materials suitable for underground coal environments

• Standardised connection systems for consistent application

• Minimal tooling requirements for quick installation

The system is designed to be installed quickly by mining crews with minimal specialised training, allowing for rapid response to borehole intersections and significantly reduced downtime.

TECHNICAL SPECIFICATIONS

System Components:

• Borehole sealing mechanism

• Gas bypass conduit

• Connection fittings

• Installation toolkit

Material Specifications:

• FRAS-compliant materials throughout

• High-durability components designed for mining conditions

• Pressure-rated connections suitable for typical gas drainage systems

Compatibility:

• Suitable for borehole diameters: 96mm (156mm coming soon)

• Compatible with standard gas drainage systems

• Adaptable to varying mining conditions and borehole orientations

Installation Requirements:

• Minimal tooling needed

• Standard installation time: 5mins

• Can be installed by regular mining crews with basic training

Operational Benefits:

• Reduces borehole treatment time by up to 50%

• Minimises production disruption during intersections

• Provides consistent, reliable sealing performance

• Eliminates need for specialised equipment

• Standardises the approach to borehole management

Safety Benefits:

• Reduces methane release into mine airways

• Minimises exposure during installation

• Decreases need for rework in hazardous conditions

• Maintains gas drainage effectiveness

• Supports compliance with safety regulations

IMPLEMENTATION PROCESS

The Proflow Gas Bypass System is designed for straightforward implementation with minimal disruption to mining operations:

1. Preparation

Standard kits are kept readily available in key locations throughout the mine, ensuring quick access when borehole intersections occur.

2. Identification

When a borehole is intersected, the crew quickly identifies the location and prepares the area for treatment.

3. Installation

Using the standardised installation procedure, the team deploys the Proflow system to seal the borehole and establish the bypass connection.

4. Verification

A simple verification process confirms the proper installation and effective gas redirection.

5. Documentation

The intersection and treatment are documented according to standard procedures, maintaining accurate records for compliance and future reference.

6. Monitoring

Treated boreholes are added to regular inspection routines to ensure ongoing system integrity.

The entire process is designed to be completed quickly and consistently, allowing mining operations to resume with minimal delay while maintaining the highest safety standards.

FIELD-PROVEN RESULTS

The ProFlow Gas Bypass System has been field-tested in active Australian underground coal mines, demonstrating significant improvements over traditional borehole management approaches:

Time Savings

Installation time reduced from hours to minutes, allowing for faster return to production.

Consistent Performance

Standardised components and procedures ensure reliable results across different crews and conditions.

Enhanced Safety

Improved sealing effectiveness minimises gas release into mine airways and reduces the need for hazardous rework.

Operational Efficiency

Simplified installation process requires minimal specialised equipment or training.

Regulatory Compliance

System design and materials meet or exceed all relevant mining regulations and FRAS requirements.

These results aren't theoretical—they're based on actual performance in some of Australia's most challenging mining environments.

READY TO TRANSFORM YOUR GAS MANAGEMENT?

The Proflow Gas Bypass System represents a significant advancement in managing one of underground coal mining's most common challenges. Developed by miners for miners, our solution addresses the real-world problems that traditional approaches often miss.

Whether you're looking to enhance safety, reduce downtime, or standardise your approach to borehole management, we're ready to show you how the Proflow system can improve your operations.

Contact us today to discuss your specific needs and learn more about implementing the Proflow Gas Bypass System at your mine.